A Commitment to Detail

Each movement is developed and assembled in Noiraigue, Canton of Neuchâtel.

The Manufacture

Nestled in the Jura mountains, our manufacture in Noiraigue continues the tradition of Swiss watchmaking that has defined this region for centuries. Here, surrounded by forests and silence, our artisans work with the focus and precision that haute horlogerie demands.

The choice of location is deliberate. Away from distraction, in a place where time moves at its own pace, we create timepieces that honour the discipline of our predecessors.

The Atelier

Natural light pours into our workshops through curved windows, bathing each workbench where movements come to life. The architecture follows the craft, with every detail conceived to support the precision of hand assembly and finishing.

Each watchmaker works at a dedicated station, combining traditional tools with modern instruments, in an environment designed for absolute focus.

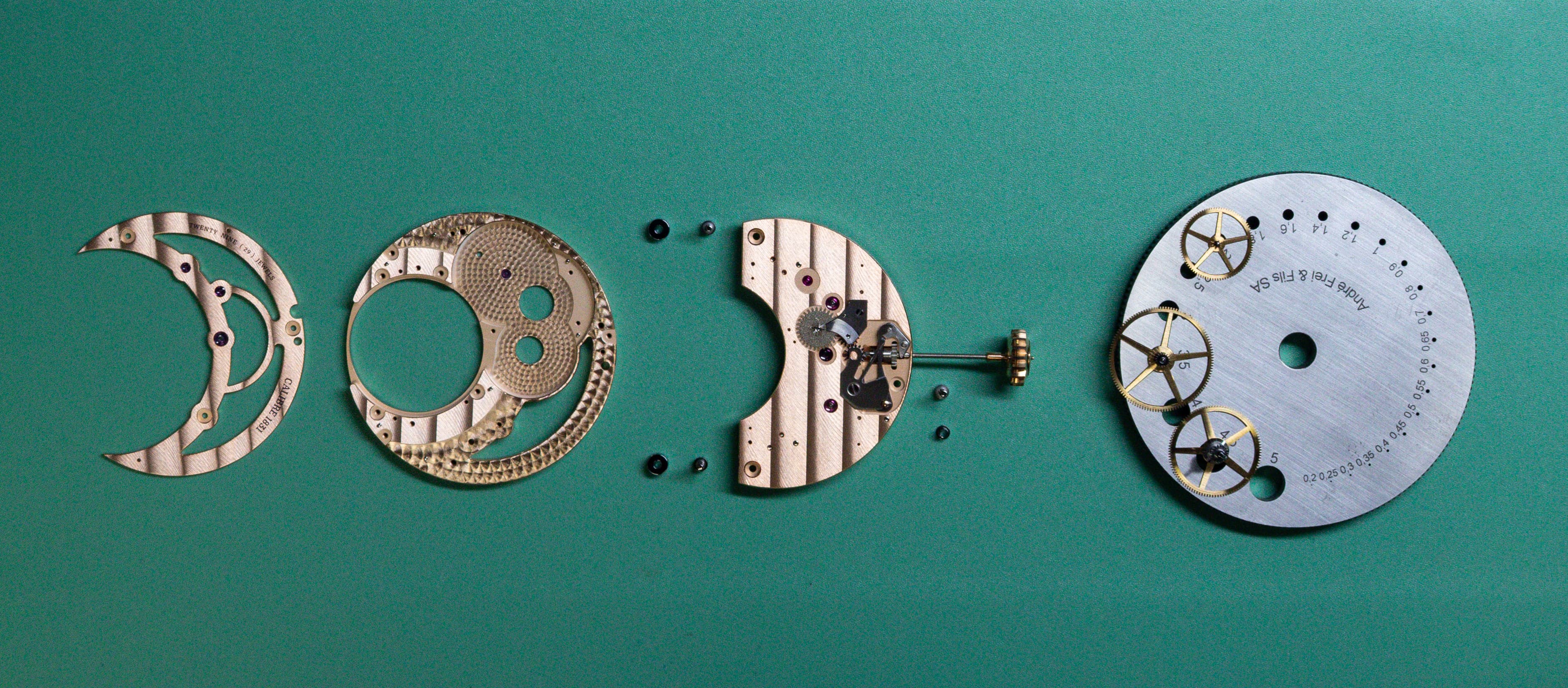

Movement Development

Our calibres are not adaptations of existing movements. They are original constructions, imagined, developed, and refined entirely in-house. From the geometry of the mainplate to the architecture of each bridge, every element belongs to a coherent whole.

The 218 components are manufactured to extreme precision, then each plate and bridge is hand-finished with traditional Geneva stripes.

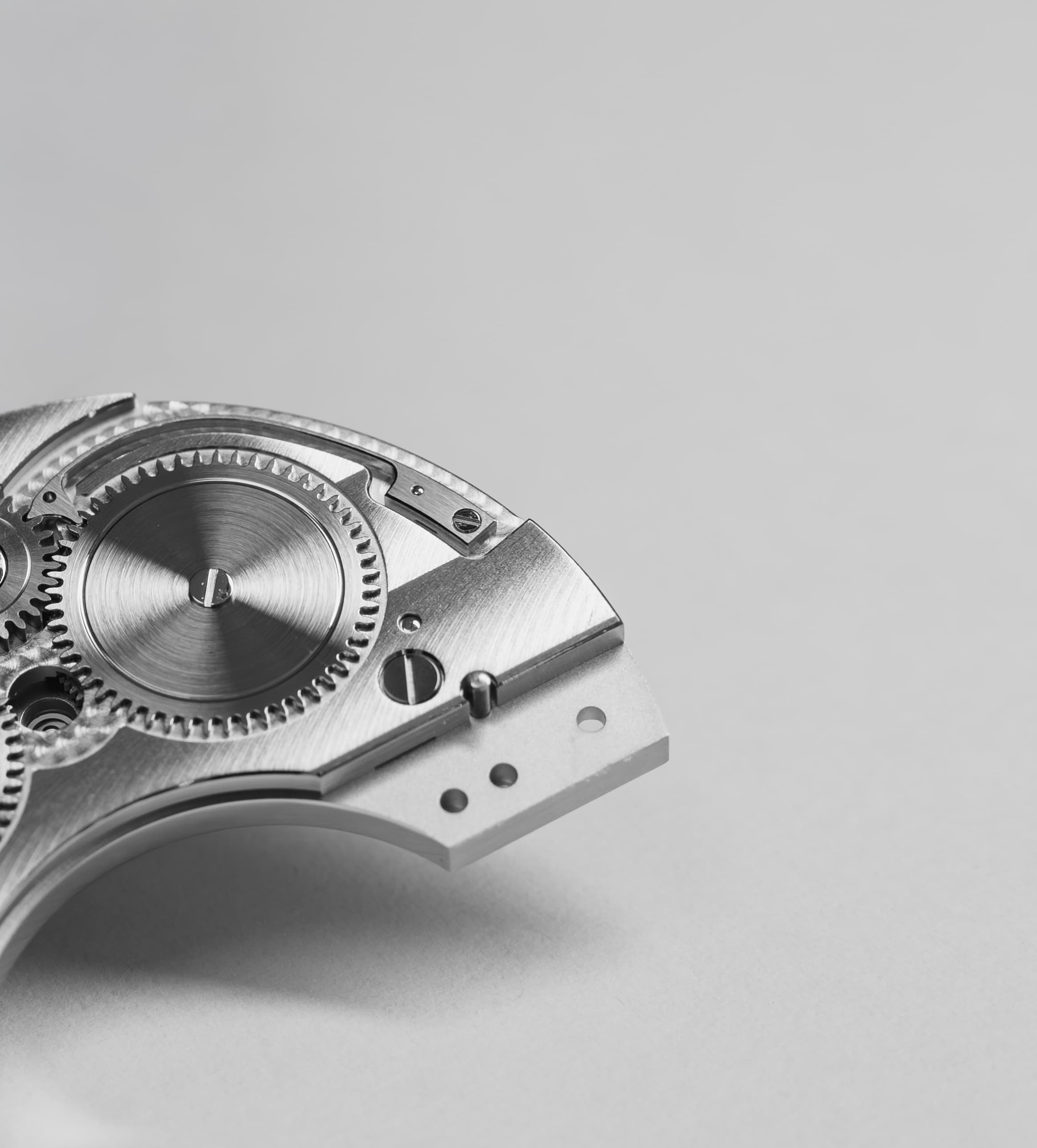

Hand Finishing

Every edge and bevel is treated with deliberate care. Bridges are finished patiently, their contours polished until they catch the light with quiet precision.

This work follows the rhythm of the human hand and eye, where judgement, sensitivity, and experience shape what no automated process can fully achieve.

The Tourbillon

At the heart of the movement lies a triple-axis tourbillon built around multi-level construction. Three concentric cages rotate simultaneously at 10, 18, and 60 seconds, compensating for gravitational effects from every angle.

Assembling this mechanism demands absolute precision. Each of the tourbillon's components must be positioned to tolerances invisible to the naked eye. A single adjustment can take hours; the complete assembly, days.

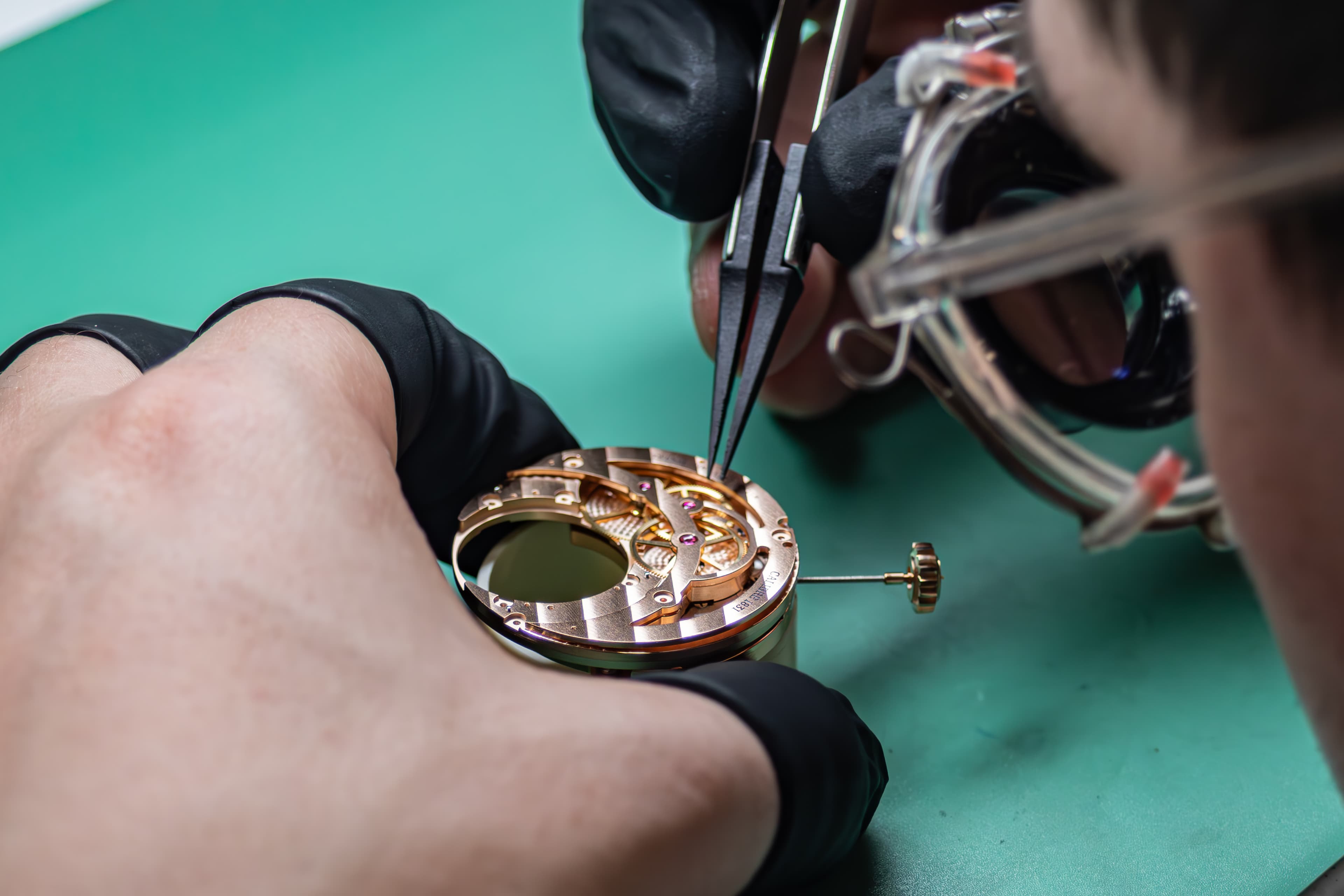

Assembly

Assembly begins once each component has been individually verified. Under magnification, parts are positioned carefully, with attention and patience.

The movement is assembled progressively, following a structured sequence where each sub-assembly is completed and checked before integration. Only once the mechanism operates as intended does the movement receive its signature bridge.

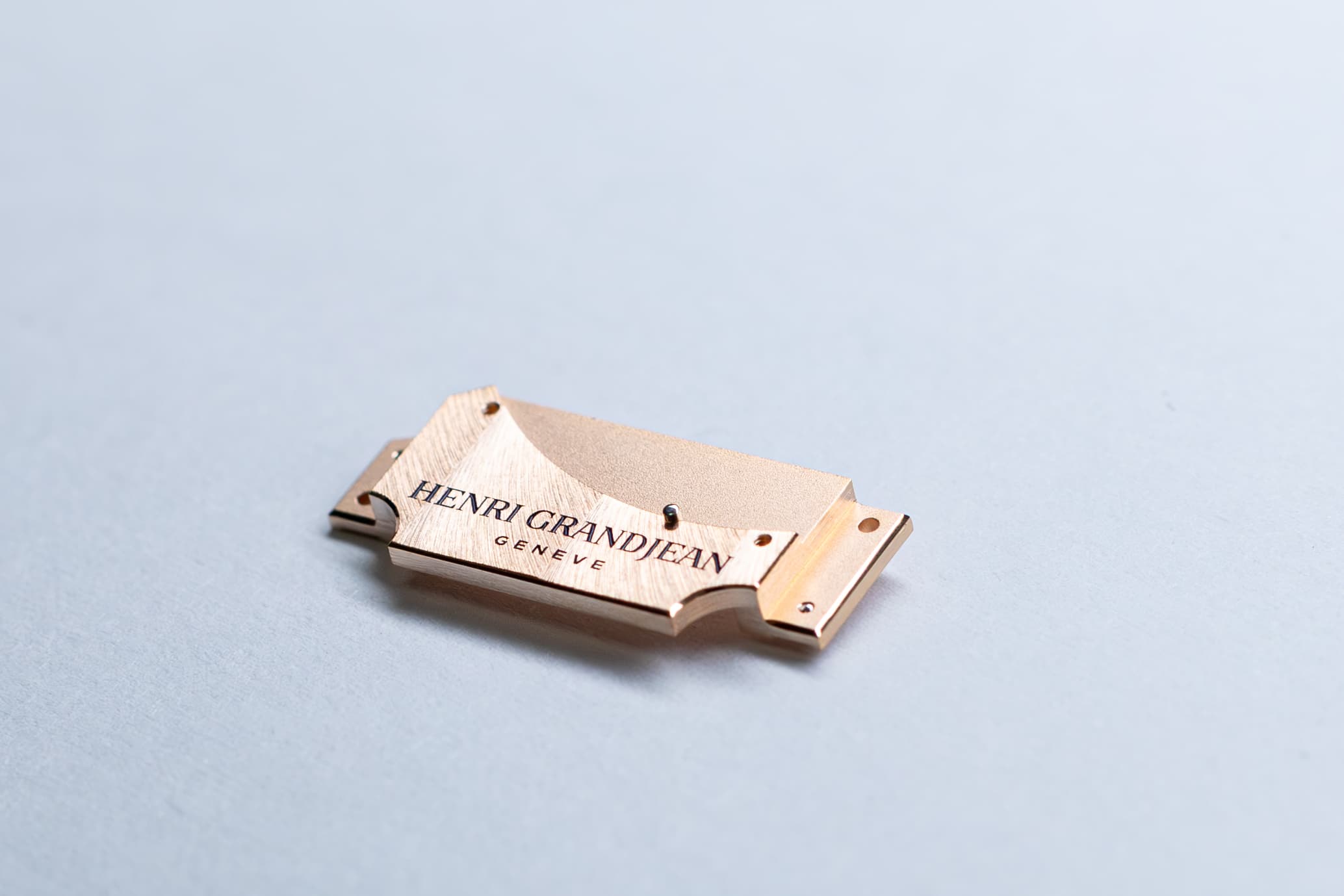

The Signature

Each movement bears our name, not as decoration, but as a statement of intent. The engraved bridge reflects our commitment to care, consistency, and discipline, values that have guided our work since 1831.

Its typography, engraving depth, and brushed surface are considered with the same attention as the mechanism itself. In haute horlogerie, every detail matters.

Quality Control

Before leaving the atelier, each movement is subjected to a series of functional checks. Rate performance is observed across multiple positions and over extended periods. Power reserve is verified, water resistance confirmed, and all functions exercised.

Our approach to testing reflects a commitment to reliability and consistency, ensuring each timepiece meets the expectations placed upon it.

Each timepiece represents thousands of hours of expertise, patience, and dedication. We invite you to discover the collection and witness the result of true manufacture.